C-AJ-0012

July 15, 2014

July 15, 2014

| ANSI/UL2079 | CAN/ULC S115 |

|---|---|

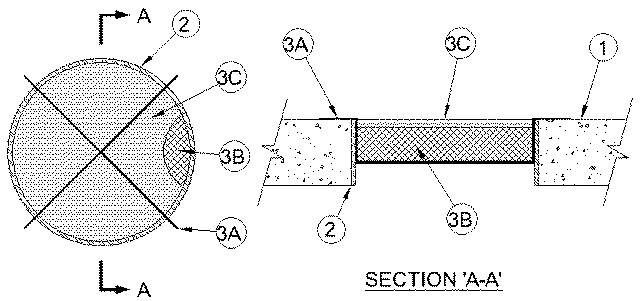

1.Floor or Wall Assembly — Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete. Wall may also be constructed of any UL Classified Concrete Blocks*. Max diam of opening is 15 in. (381 mm).See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

2.Metallic Sleeve — (Optional)-Nom 14 in. (356 mm) diam (or smaller) Schedule 10 (or heavier) steel sleeve cast or grouted into floor or wall assembly, flush with floor or wall surfaces.

3.Firestop System — The firestop system shall consist of the following:

A.Wire Hangers — Two No. 9 gauge steel wire bend in a U-shaped hanger and placed in the opening one over the other to form an "X" design.B.Packing Material — Min 2 in. (51 mm) thickness of min 4 pcf (64 kg/m3) mineral wool batt insulation firmly packed into opening as a permanent form as shown in the table below . Packing material to be recessed from top surface of floor or from both surfaces of wall as required to accommodate the required thickness of fill material.C.Fill, Void or Cavity Material* — Sealant — Min 1 in. (25 mm) thickness of fill material applied within annulus, flush with top surface of floor or with both surfaces of wall. If cracking occurs after the fill material cures, the cracks shall be sealed with sealant.

RECTORSEAL

Sealant F Rating Hr T Rating Hr Metallic Sleeve Wire Hangers Insulation thickness

in. (mm)FS900+, Metacaulk MC 150+, or Biostop BF 150+ 3 1/2 Permitted Not required 2 (51) FS900, FS901, FS903, FS903CG, FS905, FS929, FS905CG, FST901, FST903, FST905 2 2 Not permitted Required 2 (51)