August 31, 2012

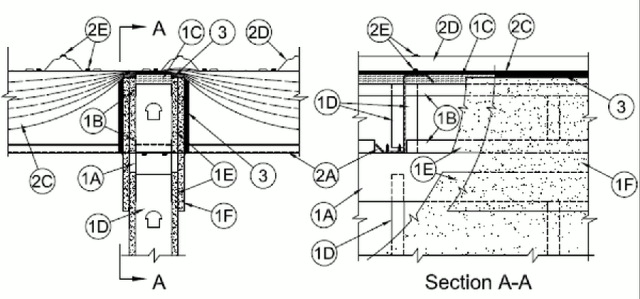

Joint Rating — 1 Hr

Nominal Joint Width — 2 in.

Class II or III Movement Capabilities — 100% Compression and Extension

1.Wall Assembly — The minimum 1 h fire rated gypsum board/steel stud wall assembly shall be constructed of the materials and in the manner specified in the individual U400, V400 or W400 Series Wall and Partition Design in the UL Fire Resistance Directory and shall include the following construction features:

A.Ceiling Deflection Channel — U-shaped channel formed from min 16 ga steel sized to accommodate steel studs (Item 1D) and provided with nom 5 in. (127 mm) flanges. Deflection channel installed perpendicular to purlins and secured to bottom flange of purlins with min No. 14 self-tapping, hex-head, plated steel or stainless steel screws.B.Steel Floor and Ceiling Runners — Floor runner of the wall assembly and the floor and ceiling runners of the cripple wall above the wall assembly shall consist of min 1-1/4 in. (32 mm) deep min 25 ga galv steel channels sized to accommodate steel studs (Item 1D). Floor runner of cripple wall aligned with and screw-attached to top of ceiling deflection channel. Ceiling runner of cripple wall installed to compress insulation (Item 2C) to min thickness of 3/8 in. (10 mm) by wedging lengths of stud (Item 1D) between the runners. Steel studs of cripple wall attached to each side of purlin web and to floor and ceiling runners with steel screws.C.Batts and Blankets* - Packing Material — Unfaced compressible mineral wool batt insulation having a nom 2 in. (51 mm) thickness before compression and a nom density of 4 pcf (64 kg/m3). Strips of nom 2 in. (51 mm) thick batt cut to width of cripple wall ceiling runner and compressed min 50 percent in thickness between cripple wall ceiling runner and insulation (Item 2C). Compression of mineral wool batt packing material to result in compression of insulation (Item 2C) to nominal 3/8 in. (10 mm) thickness.See Batts and Blankets (BZJZ) category in the UL Fire Resistance Directory or Batts and Blankets (BKNV) category in the UL Building Materials Directory for names of manufacturers.

D.Studs — Steel studs to be min 3-1/2 in. (89 mm) wide. Studs cut max 2 in. (51 mm) less in length than the wall assembly height beneath purlins with bottom nesting in and resting on the floor runner and with top nesting in ceiling deflection channel without attachment. Stud spacing not to exceed 24 in. (610 mm) O.C. Studs of cripple wall cut to length as required to compress packing material (Item 1C) and insulation (Item 2C) to min thicknesses of 1 in. (25 mm) and 3/8 in. (10 mm), respectively. Studs spaced max 24 in. (610 mm) OC.E.Gypsum Board* — (CKNX) — Min 5/8 in. (16 mm) thick gypsum board sheets installed on each side of wall. Wall to be constructed as specified in the individual U400, V400 or W400 Series Design in the UL Fire Resistance Directory except that a max 2 in. (51 mm) wide gap shall be maintained between the gypsum board of the wall assembly below the purlin and the gypsum board of the cripple wall. Top edge of gypsum board of wall assembly to be max 2 in. (51 mm) below top of ceiling deflection channel. Bottom edge of gypsum board of cripple wall to be flush with top of ceiling deflection channel. Screws securing gypsum board to steel studs of wall assembly to be located 2-1/4 in. to 2-1/2 in. (57 to 64 mm) below flange of ceiling deflection channel. Screws securing gypsum board of cripple wall to be driven into studs and runners of cripple wall. No screws are to be driven into flanges of ceiling deflection channel.F.Gypsum Board* — (CKNX) — Min 5/8 in. (16 mm) thick "rip strip" of gypsum board installed to cover first layer of gypsum board on cripple wall and to lap min 3 in. (76 mm) onto gypsum board of wall assembly on each side of wall. The "rip strip" of gypsum board is to be the same material used for the wall assembly and is to be secured to the studs and runners of the cripple wall. No screws are to be driven into flanges of ceiling deflection channel. Joints of "rip strip" to be offset from joints of gypsum board on wall assembly.Max separation between top of wall assembly gypsum board and bottom of cripple wall gypsum board (at time of installation of joint system) is 2 in. (51 mm). The joint system is designed to accommodate a max 100 percent compression or extension from its installed width.

2.Nonrated Horizontal Assembly — The nonrated horizontal assembly shall be constructed of the materials and in the manner described in the individual Roof Deck Constructions (Guide TGKX) in the UL Roofing Materials and Systems Directory and shall include the following construction features:

A.Purlin — Min 16 ga coated steel. Max spacing as specified in the individual Roof Deck Construction.B.Lateral Bracing — (Not Shown) - As required.C.Batts and Blankets* - Insulation — Any faced compressible glass-fiber blanket insulation having a min 6 in. (152 mm) thickness before compression and a min density of 0.6 pcf (9.6 kg/m3). Insulation draped over purlins prior to installation of panel clips (Item 2F) and/or metal roof deck panels (Item 2D). Side edges of the batts shall be butted or overlapped a max of 3 in. (76 mm).

See Batts and Blankets (BZJZ) category in the UL Fire Resistance Directory or Batts and Blankets (BKNV) category in the UL Building Materials Directory for names of manufacturers.

D.Metal Roof Deck Panels* — Min 26 ga coated steel. Panels continuous over two or more spans. Roof panel end laps, if required, centered over purlins with min 3 in. (76 mm) panel overlap as specified in the individual Roof Deck Construction. A line of tube sealant or tape sealant may be used at panel end and side laps.

See Metal Roof Deck Panels (TJPV) category in the UL Roofing Materials and Systems Directory for names of manufacturers.

E.Fasteners — Fasteners used for panel-to-purlin and panel-to-panel connections to be self-tapping, hex-head, plated steel or stainless steel screws with either an integral or a separate steel washer fitted with a compressible sealing washer. Fastener type, length, pilot hole diam and spacing to be as specified in the individual Roof Deck Construction.F.Roof Deck Fasteners* - Panel Clips — (Not Shown) - Panel clips used for panel-to-purlin connections to be secured to purlin through insulation as specified in the individual Roof Deck Construction.

See Roof Deck Fasteners (TLSX) category in the UL Roofing Materials and Systems Directory for names of manufacturers.

G.Thermal Spacer Blocks — (Not Shown) - Expanded polystyrene strips cut to fit between panel clips (Item 1F) as specified in the individual Roof Deck Construction. Thermal spacer blocks, when used, are to be installed between insulation (Item 2C) and metal roof deck panels (Item 2D) over purlins.

3.Fill, Void or Cavity Material* (XHHW) — Caulk — Min 5/8 in. (16 mm) thickness of fill material installed to fill any gap between top of cripple wall gypsum board and insulation (Item 2C) on each side of the wall. Additional sealant installed to fill annular space between purlin and gypsum board "rip strip" (Item 1F) on both sides of wall. Additional nom 1/2 in. (13 mm) diam bead of sealant to be applied around perimeter of purlin at its interface with the "rip strip" on each side of the wall.

RECTORSEAL — FlameSafe FS900+ Sealant, FlameSafe FS1900 Sealant, Metacaulk MC 150+ Caulk, Metacaulk 1000 Caulk, Biostop BF 150+ Caulk, Biostop 500+ Caulk