HW-D-0032

June 21, 2023

June 21, 2023

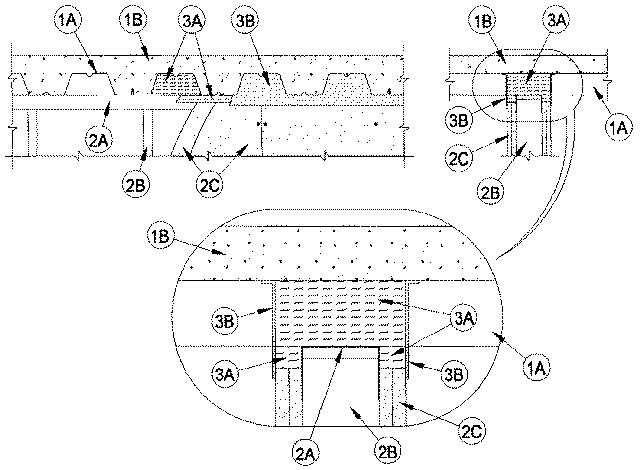

1.Floor Assembly — The fire-rated fluted steel deck/concrete floor assembly shall be constructed of the materials and in the manner described in the individual Floor-Ceiling Design in the UL Fire Resistance Directory and shall include the following construction features:A.Steel Floor And Form Units* — Max 3 in. deep galv steel fluted units.B.Concrete — Min 2-1/2 in. thick reinforced concrete, as measured from the top plane of the floor units.

2.Wall Assembly — The 2 hr fire rated gypsum board/steel stud wall assembly shall be constructed of the materials and in the manner described in the individual U400 or V400 Series Wall and Partition Design in the UL Fire Resistance Directory and shall include the following construction features:A.Steel Floor And Ceiling Runners — Floor and ceiling runners of wall assembly shall consist of galv steel channels sized to accommodate steel studs (Item 2B). Ceiling runner to be provided with 2 in. flanges. Ceiling runner installed perpendicular to direction of fluted steel deck and secured to valleys with steel masonry anchors or welds spaced max 12 in. OC.A1.Light Gauge Framing* — Slotted Ceiling Runner - As an alternative to the ceiling runner in Item 2A, slotted ceiling runner to consist of galv steel channel with slotted flanges sized to accommodate steel studs (Item 2B). Slotted ceiling runner installed perpendicular to direction of fluted steel deck and secured to valleys with steel masonry anchors spaced max 24 in. OC

CEMCO, LLC — CST

BRADY CONSTRUCTION INNOVATIONS INC, DBA SLIPTRACK SYSTEMS — SLP-TRK

STEELER INC — Steeler Slotted Ceiling RunnerA2.Light Gauge Framing —Floor and Ceiling Runners — As an alternate to the ceiling and floor runners in Item 2A, 2A1 and 2A2, floor and ceiling runners to consist of galv steel channel sized to accommodate the Light Gauge Framing* Slotted Stud (Item 2B1) or Light Gauge Framing* Slider C-Clip System (Item 2B2). Floor and ceiling runners to be provided with min 1-1/4 in. and 3 in. flanges, respectively. Ceiling runner installed perpendicular to direction of fluted steel deck secured with steel masonry anchors spaced max 12 in. OC.

STEELER INC — Floor and Ceiling RunnersA3.Light Gauge Framing*- Notched Ceiling Runner — As an alternate to the ceiling runners in Items 2A through 2A3, notched ceiling runners to consist of C-shaped galv steel channel with notched return flanges sized to accommodate steel studs (Item 2B). Notched ceiling runner installed perpendicular to direction of fluted steel deck and secured to valleys with steel masonry anchors spaced max 24 in. OC.

OLMAR SUPPLY INC — Type SCRB.Studs — Steel studs to be min 2-1/2 in. wide. Studs cut 5/8 to 3/4 in. less in length than assembly height with bottom nesting in and resting on floor runner and with top nesting in ceiling runner without attachment. When slotted ceiling runner (Item 2A1) is used, steel studs secured to slotted ceiling runner with No. 8 x 1/2 in. long water head steel screws at midheight of slot on each side of wall. Stud spacing not to exceed 24 in. OC.B1.Light Gauge Framing* —Slotted Studs — Slotted steel stud to be used in conjunction with Light Gauge Framing* —Floor and Ceiling Runners (Item 2A3). Slotted steel studs to be min 2-1/2 in. wide. Slotted studs cut 1 in. less in length than assembly height with bottom nesting in and secured to both ceiling and floor runners. Ceiling runner secured to preformed slot within steel stud by means of No. 10 by 3/4 in. long low profile head steel screw. Floor runner attached to bottom of steel stud by means of No. 8 by 1/2 in. long pan head steel screw. Slotted stud spacing not to exceed 24 in. OC.

STEELER INC — Slotted StudB2.Light Gauge Framing* —Slider C-Clip System — As an alternate to the Light Gauge Framing* —Slotted Steel Studs (Item 2B1), a Slider C-Clip System consisting of a C shaped steel clip with a slotted opening and a steel stud to be used in conjunction with Light Gauge Framing —Floor and Ceiling Runners (Item 2A3). Steel clips and studs to be min 2-1/2 in. wide. Steel clip inserted into inside flange of steel stud without attachment. Total length of steel stud cut 1 in. less than assembly height with bottom of steel stud nesting in and secured to floor runner. Floor runner attached to bottom of steel stud by means of No. 8 by 1/2 in. long pan head steel screw. Ceiling runner secured to steel C-Clip by means of No. 10 by 3/4 in. long pan head steel screw located 3/8 in. below top of ceiling runner. Top row of gypsum board screws shall be centered within the preformed slot of the C-Clip. Steel stud and steel clips spacing not to exceed 24 in. OC.

STEELER INC — Slider C Clip SystemC.Gypsum Board* — Gypsum board sheets installed to a min total thickness of 1-1/4 in. on each side of wall. Wall to be constructed as specified in the individual Wall and Partition Design in the UL Fire Resistance Directory, except that a nom 1 in. gap shall be maintained between the top of the gypsum board and the bottom of the steel floor units and the top row of screws shall be installed into the studs 3-1/2 to 4 in. below the lower surface of the floor.

3.Joint System — Max separation between bottom of floor and top of wall at time of installation of joint system is 1 in. The joint system is designed to accommodate a max 50 percent compression or extension from its installed width. The joint system consists of forming material and a fill material, as follows:A.Forming Material* — Min 8 pcf density mineral wool batt insulation cut approx 25 percent wider than the flutes and with a length approx equal to the overall thickness of the wall. Pieces stacked to height of 6 in. and then compressed 50 percent in thickness and inserted into the flutes of the steel floor units above the top of the ceiling runner. The mineral wool batt insulation is to project beyond each side of the ceiling runner, flush with wall surfaces. Nom 1-1/4 in. wide by 1-1/2 in. high strips of min 8 pcf mineral wool batt insulation are to be cut to fill the 1 in. gap between the top of the gypsum board and bottom of the steel floor units. The strips of mineral wool are compressed and firmly packed, cut edge first, into the gap between the top of the gypsum board and bottom of the steel floor units on both sides of the wall.

ROCK WOOL MANUFACTURING CO — Delta-8AB.Fill, Void or Cavity Material* — Min 1/8 in. wet thickness of fill material sprayed or troweled on each side of the wall to completely cover mineral wool forming material and to overlap a min of 1/2 in. onto gypsum board and steel deck on both sides of wall.

RECTORSEAL — Metacaulk 1200 Spray, Metacaulk 1200 Caulk Grade