HW-D-1064

December 12, 2017

December 12, 2017

| ANSI/UL2079 | CAN/ULC S115 |

|---|---|

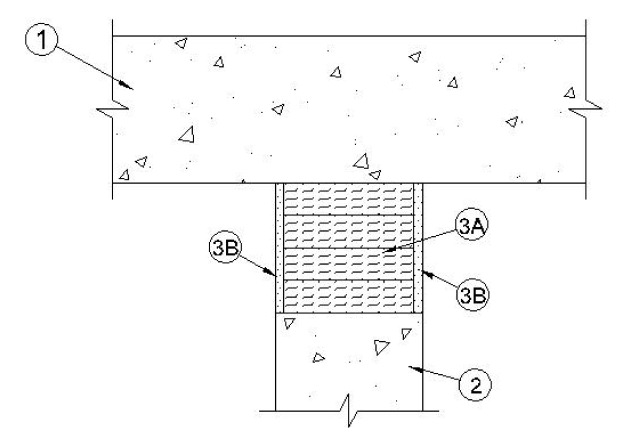

1.Floor Assembly — Min 4-1/2 in. (114 mm) thick steel-reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) structural concrete.

2.Wall Assembly — Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100-150 or 1600-2400 kg/m3) structural concrete. Wall may also be constructed of any UL Classified Concrete Blocks.

See Classified Concrete Blocks (CATZ) category in the Fire Resistance Directory for names of manufacturers.

3.Joint System — Max width of joint (at time of installation of joint system) is 4 in. (102 mm). The joint system is designed to accommodate a max 25% compression or 15.6% extension from its installed width. The joint system shall consist of the following:

A.Forming Material* — Min 4.0 pcf (64 kg/m3) mineral wool batt insulation installed in joint opening as a permanent form. Min 3-3/4 in. (95 mm) thickness of batt cut to the appropriate width and installed into joint opening such that batt sections are compressed min 33 percent in width and such that the compressed batt sections are recessed from both surfaces of wall to accommodate the required thickness of fill material. Adjoining lengths of batt to be tightly-butted with butted seams spaced min 48 in. (1219 mm) apart along the length of the joint.

INDUSTRIAL INSULATION GROUP L L C — MinWool-1200 Safing

ROCK WOOL MANUFACTURING CO — Safing Board

ROCKWOOL — SAFE Mineral Wool

THERMAFIBER INC — Type SAFB.Fill Void or Cavity Materials* — Min 1/4 in. (6 mm) thickness of fill material applied within the joint, flush with both surfaces of wall.

RECTORSEAL — FlameSafe FS 4000 Sealant, Caulk Grade or Metacaulk 835+