June 21, 2023

| ANSI/UL2079 | CAN/ULC S115 |

|---|---|

| L Rating at Ambient — 3.33 L/s/m | |

| L Rating at 204ºC— 2.1 L/s/m |

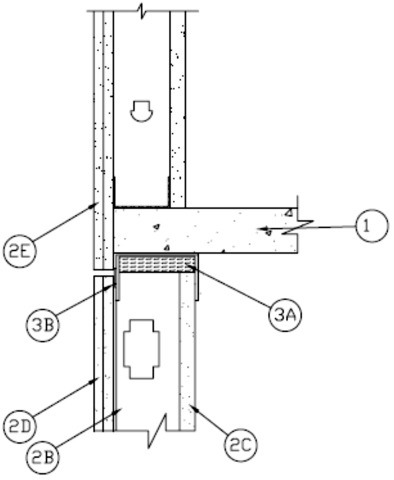

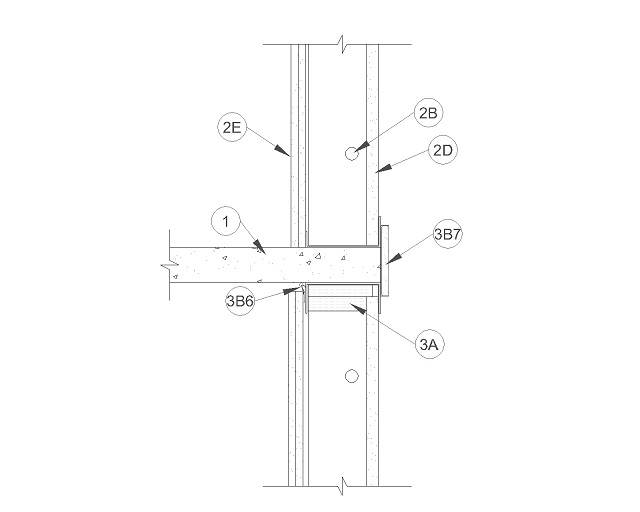

1.Floor Assembly — Min 4-1/2 in. (114 mm) thick steel reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) structural concrete. Floor may also be constructed of any min 6 in. (152 mm) thick UL Classified hollow-core Precast Concrete Units*.See Precast Concrete Units (CFTV) category in the Fire Resistance Directory for names manufacturers.

The hourly fire rating of the floor assembly shall be equal or greater than the hourly fire rating of the wall assembly

2.Shaft Wall Assembly — The 2 hr fire rated gypsum board/stud wall assembly shall be constructed of the materials and in the manner described in the individual U400 or V400 Series Wall and Partition Design in the UL Fire Resistance Directory and shall include the following construction features:

A.Steel Floor and Ceiling Runners — Floor runner U-shaped, sized to accommodate steel studs (Item 2B), fabricated from min 24 ga galv steel. Legs are to be min 1/4 in. (6 mm) longer than the maximum joint width. Runners attached to floor with steel fasteners located not greater than 2 in. from ends and not greater than 24 in OC. The ceiling runners are provided with a fill, void or cavity material and are described in Item 3.A.1.Light Gauge Framing* — Slotted Ceiling Track — (Not Shown) - As an alternate to the Item 2A, a ceiling track consisting of galv steel channel with slotted flanges may be used when Item 3B.1 fill material is utilized. Slotted ceiling track sized to accommodate steel studs (Item 2B). Legs are to be min 1/4 in. (6 mm) longer than the maximum joint width. Attached to concrete deck and spaced max 24 in. (610 mm) OC.

BRADY CONSTRUCTION INNOVATIONS INC, DBA SLIPTRACK SYSTEMS — SLP-TRK

CEMCO, LLC — CST, CST 325

MARINO/WARE, DIV OF WARE INDUSTRIES INC — Type SLTB.Studs — "C-T", "I", or "C-H" shaped steel studs to be min 2 1/2 in. (64 mm) wide and formed of min 24 ga galv steel. Studs cut 5/8 to 1-1/4 in (16 to 32 mm) less in length than assembly height with bottom nesting in and secured to floor runner. Steel studs secured to slotted leg of ceiling runner on finished side with No. 8 by 1/2 (13 mm) long wafer head steel screws at mid-height of exposed slot. Studs spaced max 24 in. (610 mm) OC.C.Gypsum Board* — 1 in. (25 mm) thick by max 24 in. (610 mm) wide gypsum board liner panels. Panels cut 1 in. (25.4 mm) less in length than floor to ceiling height. Vertical edges inserted into "T" shaped section of "C-T" studs, into holding tabs of "I" studs or into "H"-shaped section of "C-H" studs.D.Gypsum Board* — Gypsum board 1/2 or 5/8 in. (13 or 16 mm) thick, applied on finished side of wall as specified in the individual Wall and Partition Design. The boards cut a max 1 in. (25.4 mm) less in length than the floor to ceiling height. The screws attaching the gypsum board layer(s) to the "C-T", "I", or "C-H" studs shall be located between 4 and 5 in. (102 -127 mm) down from ceiling surface.E.Gypsum Board* — Gypsum board sheets installed to a min total 5/8 in. (16 mm) or 1 -1/4 in. (32 mm) thickness on each side of wall for 1 and 2 hr fire rated assemblies, respectively. Wall to be constructed as specified in the individual U400 or V400 Series Design in the UL Fire Resistance Directory except shaft side gypsum board to extends below the upper floor line overlapping the ceiling runner (Item 3) so that gypsum board overlaps intumescent strip and attached with typical steel fasteners to the ceiling runner (Item 3) of the lower level a min of 1/8 in. (3 mm).The hourly fire rating of the joint system is equal to the hourly fire rating of the wall.

3.Joint System — Max separation between bottom of floor and top of wall sheathing (non-shaft side) and gypsum board panels (shaft side) at time of installation is 5/8 in. (16 mm). The joint system is designed to accommodate a max 100 percent compression or extension from its installed width. When Item 3B.1 is used the max nominal width is 1 in. (25 mm). When item 2A.1 is used max nominal width is 3/4 in. (19 mm). See Table 1.

A.Forming Material* — Min 2 in. (51 mm) thick min 4 pcf (64 kg/m3) mineral wool batt insulation cut to friction fit 33% compression in width and installed into ceiling runner between leg of track and gypsum liner board.B1.Fill, Void or Cavity Material* — (Not Shown) A min. 25 ga composite steel angle with one 5/8 in. (16 mm) leg and one 2-1/2 in (64 mm) leg with a 5/8 in. (16 mm) strip of intumescent strip affixed along the inside 2-1/2 in (64 mm) leg. Steel angle is friction fit between the top web of the ceiling runner and the concrete deck on the finish wall side only.

CEMCO, LLC — DDA (Deflection Drift Angle)

B2.Fill, Void or Cavity Material* — (Not Shown) - As an alternate for item 3B for nominal 3/4 in. (19 mm) gap 80% compression and 30% extension between the edge of the drywall and the floor/ceiling assembly shall be filled with vinyl deflection bead with 5/16 in. (8 mm) intumescent strip and foam applied to horizontal leg that runs above the edge of the drywall. The perforated leg may be attached to the surface of the drywall with 1/2 in. (13 mm) staples every 6-8 in. (152-203 mm).

CEMCO, LLC — HOTROD XL

MARINO/WARE, DIV OF WARE INDUSTRIES INC — HOTROD XLB3.Fill, Void or Cavity Material* — (Not Shown) - As an alternate for item 3B for nominal joint 3/4 in. (19 mm) 80% compression and 30% extension. Nominal 1 in. (25.4 mm) open cell foam plug having a nominal 5/16 in. (8 mm) intumescent tape applied to the top surface of the foam profile. The foam is sized for 1 or 2 hour walls and shall be placed in the joint above the top edge of the drywall between the concrete slab. A layer of tape and joint compound can then be applied over the HOTROD Type X assembly.

CEMCO, LLC — HOT ROD Type-X

TRIM-TEX INC — Trim Tex-Hot Rod Type-X

B4.Fill, Void or Cavity Material* — (Not Shown) - As an alternate for item 3B for 1/2 in. (13 mm) nominal gap 75% compression and 25% extension 1 in. (25.4 mm) open cell foam plug having a nom 5/16 in. (8 mm) intumescent tape applied to the top surface of the foam profile. The foam is sized for 1 or 2 hour walls and shall be placed in the joint above the top edge of the drywall between the floor/ceiling assembly.

CEMCO, LLC — HOT ROD Type-X

TRIM-TEX INC — Trim Tex-Hot Rod Type-X

B5.

Fill, Void or Cavity Material – As an alternate to Item 3B4 (not shown), fire barrier material adhered to corrugated metal or plastic and provided with flanges of same material. Assembly to be installed on one side between gap in Item 2D where gypsum board extends below the bottom of floor, in accordance with the installation instructions provide with the product.

CEMCO, LLC — FAS-093X or FAS-093-V

B6. Fill, Void or Cavity Material* — (Config B)— (Not Shown) - For nominal 1/4 in. (6mm) gaps 100% compression/ extension or 1/2 in. (12mm) compression only. As an alternate to DDA (Item 3B1) a composite corrugated vinyl profile with a 1-1/8 in. (28 mm) wide leg and a 1/4 in. (6 mm) bubble gasket along the upper edge. A 1/4 in. (6 mm) wide intumescent strip affixed along the inside 1-1/8 in. (28 mm) leg. Composite vinyl profile is attached to the leg of the ceiling runner/track with No. by 1/2 in. (12 mm) long framing screws or adhesively attached with double sided foam tape.

CEMCO, LLC — Fire Gasket 0.5

MARINO/WARE, DIV OF WARE INDUSTRIES INC — Fire Gasket 0.5

B61. Fill, Void or Cavity Material* — (Config B) -For nominal 1/2 in. (12 mm) gaps 100% compression/ extension or 1 in. (25 mm) compression only. As an alternate to DDA (Item 3B1), a composite corrugated vinyl profile with a 1-1/2 in. (38 mm) wide leg and a 3/8 in. (10 mm) bubble gasket along the upper edge. A 5/8 in. (16 mm) wide intumescent strip affixed along the inside 1-1/2 in. (38 mm) leg. Composite vinyl profile is attached to the leg of the ceiling runner/track with 1/2 in. (13 mm) No. 8 framing screws or adhesively attached with double sided foam tape.

CEMCO, LLC — Fire Gasket 1.0

MARINO/WARE, DIV OF WARE INDUSTRIES INC — Fire Gasket 1.0

B7. Fill, Void or Cavity Material – Required for configuration B. A nom 20 gauge steel angle encased on 3 sides over a nom 6 in. (152 mm) or 10 in. (254 mm) wide layer of 5/8 in. (16 mm) Type X gypsum board Classified for Fire Resistance. Strap to be centered over floor assembly or steel shape and overlap a min of 1-1/2 in. (37 mm) Strap be secured to floor runner (Item 2A) with 1-1/8 in. (29 mm) long drywall anchors spaced a max 12 in. (305 mm) on center. Also attached to ceiling runner or track (Item 2A or 2A.1) with 1-1/8 in. (29 mm) long drywall anchors a max of 3/8 in. (10 mm) below the track web and a max of 12 in. (305 mm) O.C. Face of steel angle to be in contact with face of wall.

CEMCO, LLC — FireRip Strap 6, FireRip Strap 10.

Table 1

Model

Nominal Joint Size, in. (mm)

Cycle Rating, %

DDA (Deflection Drift Angle) 5/8 (16)

Compression

100

Extension

100

3/4 (19)

Compression

100

Extension

100

1(25.4

Compression

100

Extension

100

HOTROD Type-X 3/4(19)

Compression

80

Extension

33

HOTROD Type-XL 3/4(10)

Compression

80

Extension

33

FireRip-Strap 6 or FireRip Strap 10 5/8. 3/4 or 1 in. (16, 19 or 25 mm)

Compression

90

Extension

100

Fire Gasket 0.5 1/4 in. (6 mm)

Compression

100

Extension

100

1/2 in. (13 mm)

Compression

100

Extension

0

Fire Gasket 1.0 1/2 in. (13 mm)

Compression

100

Extension

100

1 in. (25 mm)

Compression

100

Extension

0

C.Fill, Void or Cavity Material* — Sealant — (Not Shown, optional) -Sealant may be used to seal any gaps above ceiling runner, and at butt joints in Fill, Void or Cavity Material, FireRip Strap (Item 3B7) to maintain L Ratings.

RECTORSEAL — Metacaulk 1200, Biostop 750, FlameSafe FS3000, Metacaulk 1500, or Biostop 800 Spray.