HW-D-0235

May 27, 2014

May 27, 2014

Assembly Rating — 2 Hr

Nominal Joint Width — 2 In.

Class II Movement Capabilities — 25% Compression or Extension

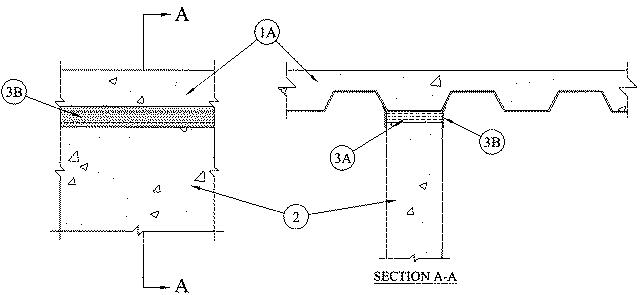

1.Floor Assembly — The fire-rated fluted steel deck/concrete floor assembly shall be constructed of the materials and in the manner described in the individual D900 Series Floor-Ceiling Design in the UL Fire Resistance Directory and shall include the following construction features:

A.Steel Floor and Floor Units* — Max 3 in. (76 mm) deep galv steel fluted floor units.B.Concrete — Min 2-1/2 in. (64 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete, as measured from the top plane of the floor units.

1A.Roof Assembly — (Not Shown) — As an alternate to the floor assembly, a fire-rated fluted steel deck roof assembly may be used. The roof assembly shall be constructed of the materials and in the manner described in the individual P900 Series Roof-Ceiling Design in the UL Fire Resistance Directory. The hourly rating of the roof assembly shall be equal to or greater than the hourly rating of the wall assembly. The roof assembly shall include the following construction features:

A.Steel Roof Deck — Max 3 in. (76 mm) deep galv steel fluted roof deck.B.Roof Insulation — Min 2-1/4 in. (57 mm) thick poured insulating concrete, as measured from the top plane of the roof deck.

2.Wall Assembly — Min 6 in. (152 mm) thick steel reinforced lightweight or normal weight (100 to 150 pcf or 1600-2400 kg/m3) concrete. Wall to be parallel to and centered under the valleys of the steel floor units. Wall may also be constructed of any UL Classified Concrete Blocks*.

See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

3.Joint System — Max separation between bottom of floor and top of wall is 2 in. (51 mm). The joint system is designed to accommodate a max 25 percent compression and extension from its installed width. The joint system consists of a forming material and a fill material, as follows:

A.Forming Material* — Min 4 pcf (64 kg/m3) density mineral wool batt insulation cut into strips with a width equal to the overall thickness of wall. Strips compressed 50 percent in thickness and inserted into gap between the top of the wall and the bottom of the steel floor unit or roof deck.B.Fill, Void or Cavity Material* — Spray — Min 1/8 in. (3.2 mm) wet thickness of fill material spray or brush applied on each side of the wall to completely cover the mineral wool forming material and to overlap a min 1/2 in. (13 mm) onto concrete wall and the steel floor units or roof deck on both sides of wall.

RECTORSEAL — FlameSafe FS3000, Metacaulk 1200, 1500 or Biostop 750, 800 Spray