December 6, 2023

| ANSI/UL2079 | CAN/ULC S115 |

|---|---|

|

Assembly Ratings — 2 and 3 Hr (See Item 2 and 3) |

F Ratings — 2 and 3 Hr (See Item 2 and 3) |

|

Nominal Joint Width - 1 In. |

FT Ratings — 2 and 3 Hr (See Item 2 and 3) |

|

Class II or III Movement Capabilities — 12.5% or 18% Compression or Extension (See Item 3) |

FH Ratings — 2 and 3 Hr (See Item 2 and 3) |

|

FTH Ratings — 2 and 3 Hr (See Item 2 and 3) |

|

|

Nominal Joint Width - 25 mm |

|

|

Class II or III Movement Capabilities — 12.5 % or 18% Compression or Extension (See Item 3) |

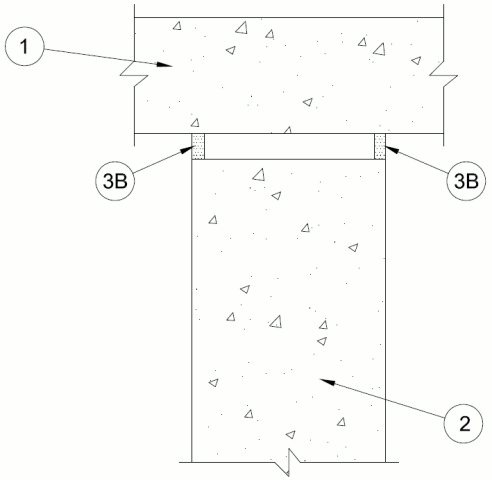

1.Floor Assembly — Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100 - 150 pcf or 1600-2400 kg/m3) structural concrete. Floor may also be constructed of any min 6 in. (152 mm) thick UL Classified hollow-corePrecast Concrete Units*.See Precast Concrete Units (CFTV) category in the Fire Resistance Directory for names of manufacturers.

2.Wall Assembly — Min 4-1/2 in. (114 mm) or min 8 in. (203 mm) thick reinforced lightweight or normal weight (100 - 150 pcf or 1600-2400 kg/m3) structural concrete. Wall may also be constructed of any UL Classified Concrete Blocks*.See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

The hourly ratings are 2 hr for walls less than 8 in. (203 mm) and or sealant (Item 3B) less than 1/2 in. (13 mm), 3 hr for walls 8 in. (203 mm) thick and thicker.

3.Joint System — Max separation between bottom of floor and top of wall (at time of installation of joint system) is 1 in. (25.4 mm).. The movement capabilities of the joint system is dependent the type and thickness of fill material as described in the table below. The joint system shall consist of the following:A.Packing Material — (Optional, not shown) - Open or closed cell polyurethane foam backer rod used as a form to prevent the leakage of fill material. Packing material to be recessed from both surfaces of the wall as required to accommodate the required thickness of fill material.B.Fill, Void or Cavity Material* - Sealant — Sealant applied within the joint, flush with both surfaces of wall. The thickness of fill material is dependent upon the type of fill material and percent compression and extension of the joint system as shown in the table below.

RECTORSEAL — FlameSafe FS 900+, FS 1900, Metacaulk 1000, Metacaulk MC 150+, Metacaulk 350i, Metacaulk MC1200, Biostop 350i, Biostop BF 150+, Biostop 500+ or Biostop 750, Metacaulk 1200 Caulk Grade

Fill, Void, or Cavity Material

Material thickness, in. (mm)

Percent compression and/or extension

Hourly rating

Metacaulk MC 150+, Metacaulk 1000 Caulk, Metacaulk 1200 Spray, Metacaulk 1200 Caulk Grade

1/4 (6)

±18

2

FlameSafe FS 900+, FS 1900, Metacaulk 1000, Metacaulk MC 150+, Metacaulk 350i, Metacaulk MC1200, Biostop 350i, Biostop BF 150+, Biostop 500+ or Biostop 750

1/2 (13)

±12.5

2 or 3