HW-D-0109

October 21, 2015

October 21, 2015

Assembly Ratings - 2 and 3 Hr (See Item 3A)

Nominal Joint Width — 2 In.

Class II Movement Capabilities — 25% Compression or Extension

L Rating At Ambient - Less Than 1 CFM/Lin Ft

L Rating At 400 F - Less Than 1 CFM/Lin Ft

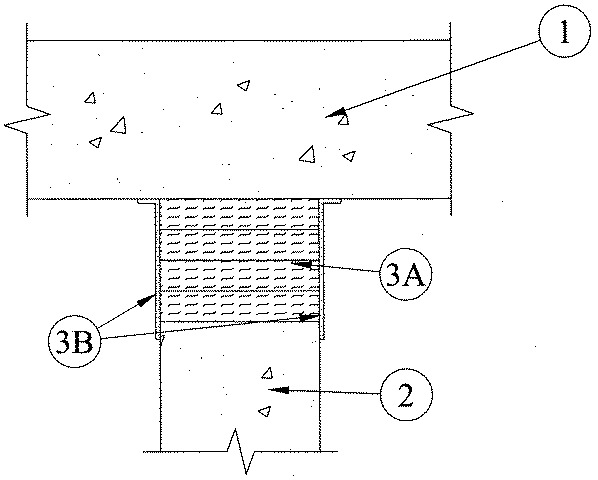

1.Floor Assembly — Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) structural concrete. Floor may also be constructed of any min 6 in. (152 mm) thick UL Classified hollow-core Precast Concrete Units* .

See Precast Concrete Units (CFTV) category in the Fire Resistance Directory for names of manufacturers.

The hourly fire rating of the floor assembly shall be equal or greater than the hourly fire rating of the wall assembly.

2.Wall Assembly — Min 6 in. (152 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) structural concrete. Wall may also be constructed of any UL Classified Concrete Blocks* .

See Concrete Blocks* (CAZT) category in the Fire Resistance Directory for names of manufacturers.

The hourly fire rating of the joint system is equal to the hourly fire rating of the wall assembly.

3.Joint System — Max separation between bottom of floor and top of wall (at time of installation of joint system) is 2 in. (51 mm). The joint system is designed to accommodate a max 25 percent compression or extension from it's installed width. The joint system shall consist of the following:

A.Forming Material* — Min 4 pcf (64 kg/m3) mineral wool batt insulation installed in joint opening as a permanent form. Pieces of batt cut to min width of 6 or 6-5/8 in. (152 or 168 mm) for 2 and 3 hr rated assemblies, respectively, and installed edge-first into joint opening, parallel with joint direction, such that batt sections are compressed min 50 percent in thickness and that the compressed batt sections are recessed from each surface of the wall as required to accommodate the required thickness of fill material.

INDUSTRIAL INSULATION GROUP L L C — MinWool-1200 Safing

JOHNS MANVILLE — Safing

ROCK WOOL MANUFACTURING CO — Delta Board

ROCKWOOL MALAYSIA SDN BHD — SAFE

ROCKWOOL — SAFE

THERMAFIBER INC — SAFB.Fill, Void or Cavity Material* — Spray — Min 1/8 in. (3.2 mm) wet thickness or 1/16 in. (1.6 mm) dry wet thickness of fill material applied within the joint, flush with each surface of wall and lapping a min 1/2 in. (13 mm) onto the bottom surface of the floor and each surface of wall.

RECTORSEAL — FlameSafe FS3000, Metacaulk 1200, 1500 or Biostop 750, 800 Spray