FW-D-0013

April 6, 2006

April 6, 2006

Assembly Rating — 3 Hr

Nominal Joint Width — 1 in.

Class II and III Movement Capabilities — 25% Compression or Extension

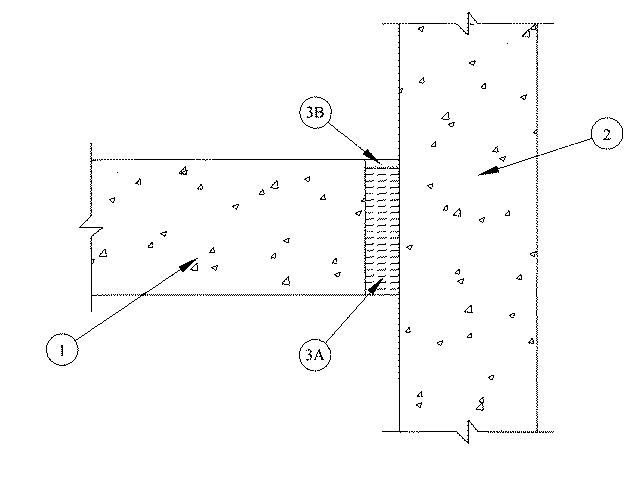

1.Floor Assembly — Precast Autoclaved Aerated Concrete* — Min 4 in. (102 mm) thick as specified in Design No. K909, K910, P932 or P933 in the UL Fire Resistance Directory.

AERCON FLORIDA L L C — Types AC-3.3, AC-4, AC-4.4, AC-6, AC-6.6

2.Wall Assembly — Precast Autoclaved Aerated Concrete* — Min 4 in. (102 mm) thick as specified in Design No. U919 or U920 in the UL Fire Resistance Directory.

AERCON FLORIDA L L C — Types AC-2, AC-3.3, AC-4, AC-4.4, AC-6, AC-6.6

3.Joint System — Max width of joint (at time of installation of joint system) is 1 in. (25 mm). The joint system is designed to accommodate a max 25 percent compression or extension from its installed width. The joint system shall consist of the following:

A.Forming Material* — Min 4 pcf (64 kg/m3) mineral wool batt insulation installed in joint opening as a permanent form. Min 3-1/2 in. (89 mm) thickness of batt cut to the appropriate width and installed into joint opening such that batt sections are compressed min 50 percent in width and such that the compressed batt sections are recessed from the top surface of floor to accommodate the required thickness of fill material. Adjoining lengths of batt to be tightly-butted with butted seams spaced min 24 in. (610 mm) apart along the length of the joint.

ROCK WOOL MANUFACTURING CO — Delta Safing BoardB.Fill, Void or Cavity Material* — Min 1/2 in. (13 mm) thickness of fill material applied within the joint, flush with top surface of wall.

RECTORSEAL — Metacaulk 1200 Spray, Metacaulk 1200 Caulk Grade or Metacaulk 1200 SL